The R9 system allows you to monitor your refrigeration equipment in real time, and will alert you if temperatures move outside of a preset range. Where you set your alert levels will determine how accurately, and how frequently you will receive alerts. To receive accurate and useful temperature alerts, you will need to know the following information:

- What temperature is my equipment currently operating at?

- What level should I set temperature alert trigger points?

What temperature is my equipment currently operating at? Most restaurants or equipment operators will already measure and know the temperature their equipment is operating at. But, taking measurements by hand means that detailed performance of the equipment is generally unknown. The FDA has guidelines for the proper temperatures at which refrigerators and freezers should operate (www.fda.gov). According to the FDA, for food service, a refrigerator should operate at or below 40F or 4C. A freezer should operate at or below 0F or -18C. Note that some foods start to freeze at 36F, so an optimal refrigeration temperature is about 38F. These are the optimal set points, but in implementation, the temperatures will fluctuate in a “normal” operating range. The measured temperature will vary as the compressor turns on/off or the speed changes, defrost cycles run, or equipment is loaded with warm food. Leaving the door open to load and unload the unit will change the measured temperature. Commercial refrigerators and freezers will typically do a better job of regulating temperature, as compared to consumer equipment. The easy way to determine the temperature range your equipment is operating at, is to view a graph of your equipment operation for a few days to a week (using the R9 system). It is important to note, if the resulting temperature graphs do not show temperatures in a range where you want your equipment to run, you should adjust the temperature settings to an appropriate level. Calling a repair technician to assist may be required.

A few important points:

- Food or product package temperatures are not the same as the instantaneous measured ambient temperature of a refrigerator or freezer.

- Packages will hold their temperature near the average temperature (over time) of the equipment set temperature.

- It takes time for food or packages to warm (thaw) when temperatures become elevated inside equipment. Momentary elevation of the temperature is normal.

- In the case of elevated food temperatures for prolonged periods, the FDA has guidelines for directly measuring food temperature to determine if it is still safe to consume.

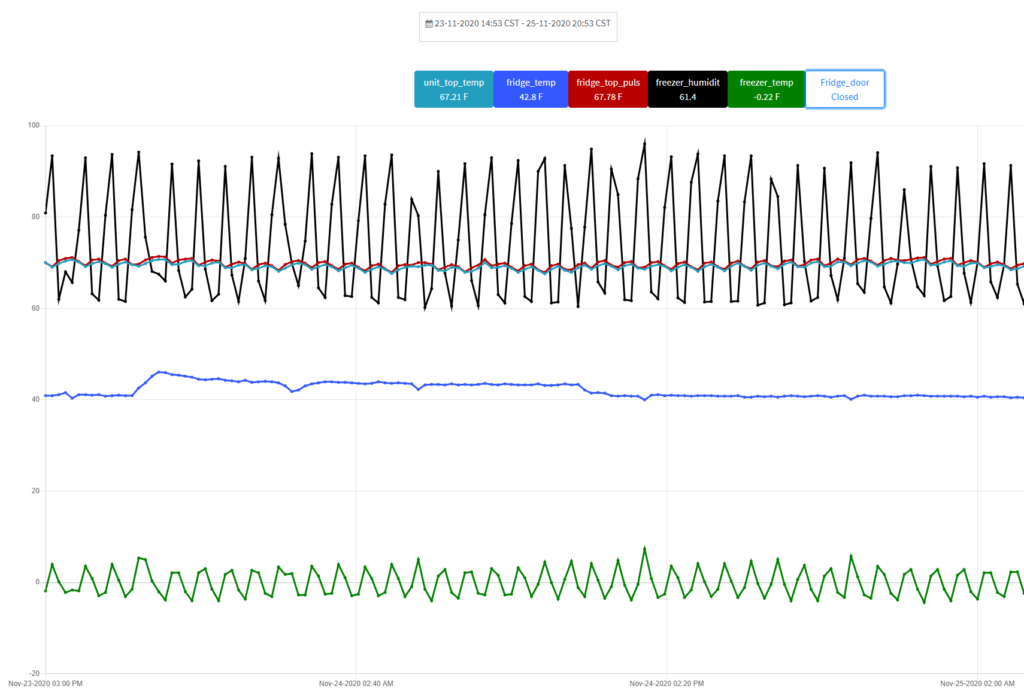

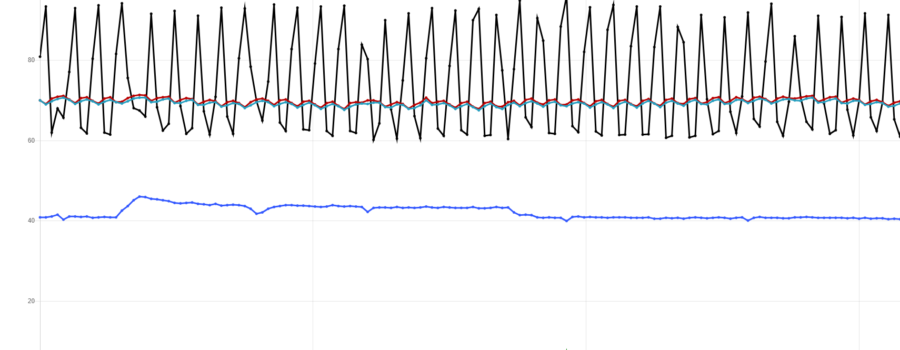

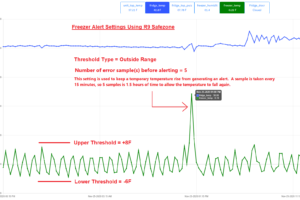

The example Safezone chart (click on image at top of page to expand a hi-res view), indicates freezer temperature and humidity, and also refrigerator temperature from a working appliance. Similar charts of your equipment temperature operation can be viewed using the Safezone main dashboard (via the web portal). You can click on the chart symbol on the dashboard to view a chart for all the sensor channels for that node.

![]()

The measured freezer temperature (green trace in image) repetitively runs from -5F up to about 6F over and over (averaging 0F). The zig-zag appearance is due to the freezer compressor turning on and off. It is best to set your trigger alert points just above, and below the normal operating range of your equipment. In the case of this freezer, good set points would be about +10F and -10F. You might observe occasional excursions from this temperature range, due to equipment defrost cycles, or from loading food, for example. To prevent un-necessary alerting from this, there are filter mechanisms in the Safezone portal that are available to implement (parameter = allowed error samples before reporting). This will allow these temperature variations to occur without generating an alert message. Refer to separate documents to see specific steps on how to set alert levels in the R9 Safezone web portal.